Packaging & Delivery

| Packaging Details: | wooden case/ wooden pallet/strench film/ as customer requirement |

|---|---|

| Delivery Detail: | 30 -40 days |

Free spare part list

No Spare parts name Quantity

1 Spring for sending material 100 pcs

2 High temperature tape 1box

3 Heating sheet 2 pcs

4 Tool 1SET

5 Punch board 2pcs

6 Synchronic belt 1pcs

7 Punch knife 4pcs (2size)

8 Temperature meter 1pc

9 Voltage adjust meter 1pc

10 Close switch 1pc

youtube video: https://www.youtube.com/watch?v=eBm7oYhYp48&feature=youtu.be

| Packaging Details: | wooden case/ wooden pallet/strench film/ as customer requirement |

|---|---|

| Delivery Detail: | 30 -40 days |

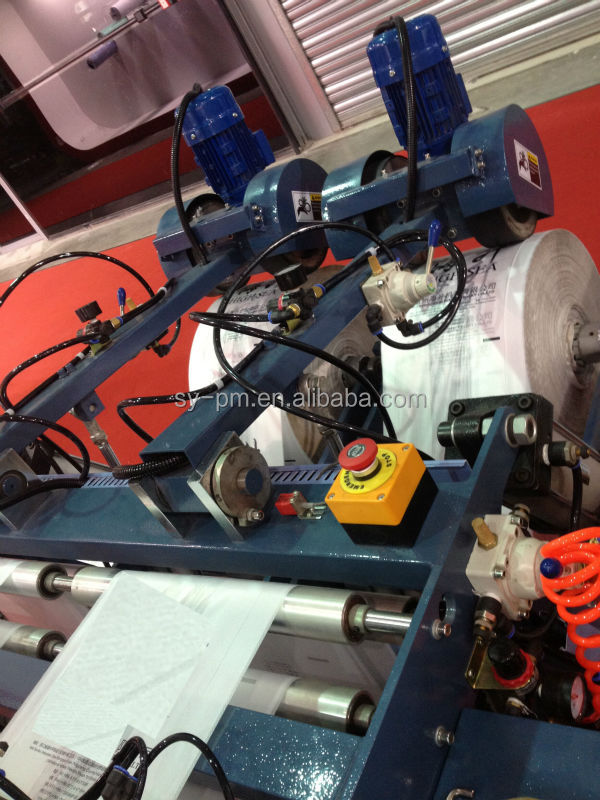

Technical Features:

1. Applications: FQGS-450X2 Lines model bag making machine is

suitable for making print bags or no-print bags.

2. Double line production system: this machine can produce print or

no-print bags by two production lines. In this way, the labor salary is

saved.

3. Fully automatic: it can do one-line production of the following steps:

heat sealing, heat cutting, punching, sending bags out by conveyor belt,

folding bags, and waste film delivering. All the above steps is done by

one machine.

4. Independent control system: the sealing and cutting device adopts

one computer to control the machine. The punch device adopts

another computer to control. Therefore, it is independent control

system. If moving the punch unit out, the sealing and cutting device

also can make flat bags.

5. Double punch: Two air cylinder device will be installed on the

machine to do “M”shape cutting with heavy power. Moreover, two

“M” shape knives will be installed on the machine to do two line

punch production easily.

6. Bags Conveyor belt: it adopts conveyor belt to send bags out in order.

7. Waste film conveyor belt: the waste film under the machine will be

delivered out by another conveyor belt under the machine.

8. Double photo cell: Two photo cells will be installed on the sealing

and cutting unit to track the print mark for print bags in two

production line.

9. Its machine has the following more features: automatic

temperature control, double driver, double sealing knife,

automatic counting system, alarm system

Main Technical Parameters

Model FQGS-450X2 lines

Bag width 200-400mm

Bag length 300-700mm

Bag thickness 0.01-0.05mm

Speed 250-300 pcs/minute

air Compressed 10HP

Power Required 12.5KW

Machine weight 2600KG

Dimension (L×W×H) 7000x1600x1800mm

SPEED: 150M/MIN

No. Bag length Speed

1 BAG LENGTH 700mm 214bag/line/min, 428bags/2 line /

min

2 Bag length 600mm 250bag/line/min, 500bags/2line /

min

3 Bag length 500mm 300bag/line/min,

600bags/2line/min

Accessory Name Origin Type Amount

Three-phase motors Italy MGM Y90L—1,5KW 1pcs

Discharge motors,AC Italy MGM ZYT22-22018----370W 2 pcs

Yaskawa servo motor Japan Yaskawa4.4KW 2pcs

Punching machine computer LCD Japan Mitsubishi PLC 1 pcs

Feeder photoelectric Germany SICK 2 pcs

Unwinder photoelectric Germany SICK 2 pcs

inverter Taiwan Delta 4 pcs

Feeding solenoid valve Taiwan Mindman 2 pcs

Temperature Controller Taiwan Yangming 3 pcs

Punching Machine solenoid valve Taiwan Mindman 4V210-08 5 pcs

Pressurized cylinder Taiwan Jiuli T63-150-15-3T 2 pcs

Button switch Japan Schneider 6 pcs

Breaker Japan Schneider 4 pcs

Punching machine motor Italy MGM 1 pcs

Reducer Italy MGM 1 pcs

Potentiometer Japan Omron N pcs

Bearing Japan NSK N pcs

EPC correction system