Packaging & Delivery

Automatic Roll Changing Plastic Vest Rolling Bag Making Machine is with Film wrapped and then exporting standard wooden case, 6 machines can be loaded in a 40 ft container, one year guarantee time, whole life technician support, a set of tools, a box of vulnerable parts, English operation manual.

| Packaging Details: | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

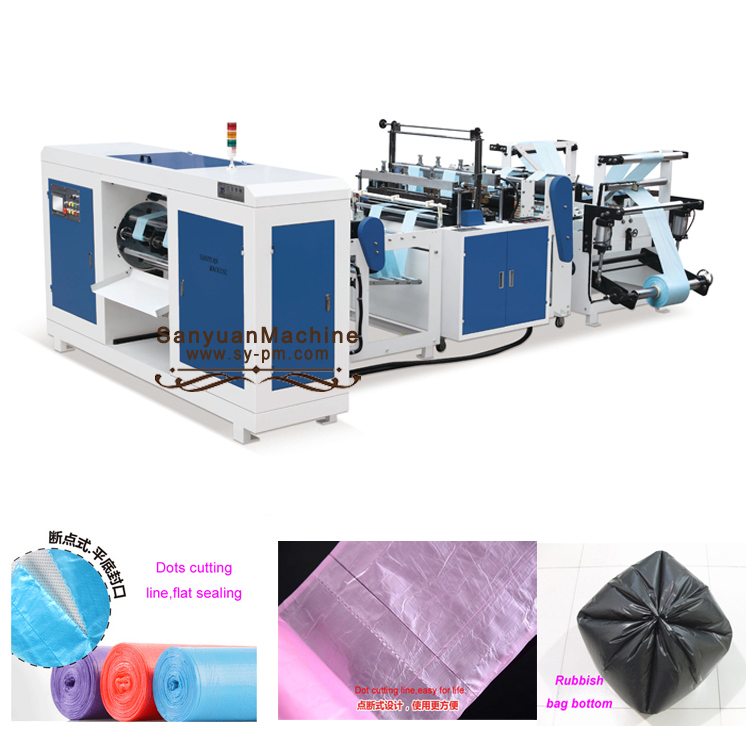

High speed vest rolling plastic bag making machine

Computer Control

Cold Cutting

Left and Right two line

120pcs/min/line

>>Characteristic

It is suitable for dots-severing & cutting all kinds of plastic film and color film. It is an ideal equipment for roll bag, trash bag, table film, flat bag, etc.

- Photoelectric control feeding system: It adopts photoelectrical cell control unwinding.

- If lost sign, machine will stop automatically.

- It adopts double working position for winding, unwinding and sealing.

- It adopts computer to control. It can set bag length freely.

- Auto counting and alarm system

- Automatic temperature control

- Easy operation, stable function and good sealing properties, suitable to make garbage bag.

- Multi-function, by changing the dot-severing knife into flat knife,and change rewinding stand into flat platform, this machine can also make bottom sealing and cutting vestbags.

>>Main Technical Parameters

|

MODEL |

FQCD500H |

|

Bag Width (Max) |

120-200mm×2 |

|

Bag Length |

400-1000mm |

|

Converting Thickness |

0.01-0.02mm |

|

Accuracy Length |

±1 |

|

Speed Cut/Min |

120 |

|

Motor |

1.1kw/1.5HP |

|

Heater |

3kw |

|

Power Required |

6.5KW |

|

Dimension (L×W×H) |

4100×1620×1500mm |

|

Gross Weight |

1100kg |

>> Free Spare Parts

|

Spare parts name |

Quantity | |

|

1 |

Spring for sending material |

100pcs |

|

2 |

High temperature tape |

1box |

|

3 |

Heating sheet |

2pcs |

|

4 |

Tool |

1set |

|

5 |

Punch board |

2pcs |

|

6 |

Synchronic belt |

1pcs |

|

7 |

Punch knife |

4pcs (2size) |

|

8 |

Temperature meter |

1pc |

|

9 |

Voltage adjust meter |

1pc |

|

10 |

Close switch |

1pc |