China Sanyuan Brand FQCT Model Heat sealing and cold cutting

bag making machine

1.This machine is suitable for sealing and cutting the plastic film as high density polyethylene(HDPE), low density polyethylene (LDPE).

2.It can be used for automatically sealing and cutting various plastic film with color printing or without color printing to be bags continuous. It is best equipment for making plastic vest bags and flat bags.

3.This machine is controlled by microcomputer system, sleepless regulated by step motor, featured by high-position stop, stable feeding and accurate positioning etc. The finished bags arc neat, stiff and smooth, with beautiful Appearance.

Characteristics :

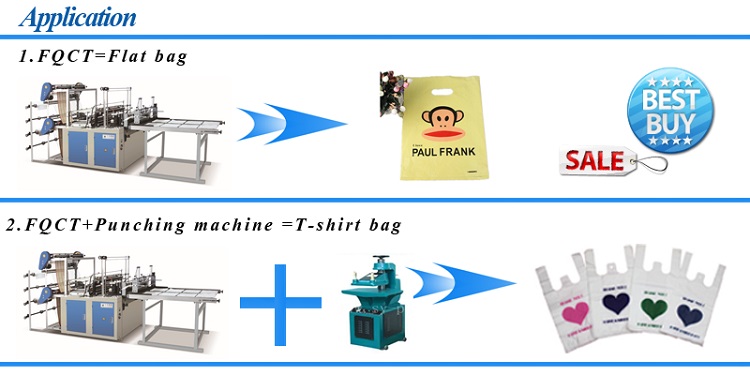

1.Applications :

FQCT-700 Model cutting machine is suitable for making print bags or no-print bags.

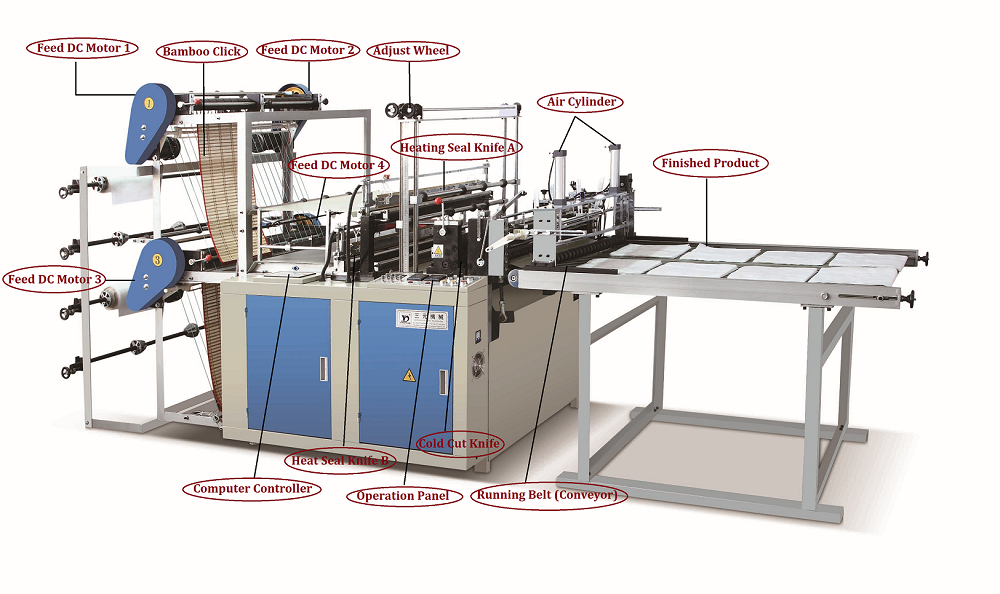

2.Automatic:

It can do one-line production of the following steps: heat sealing and cold cutting.

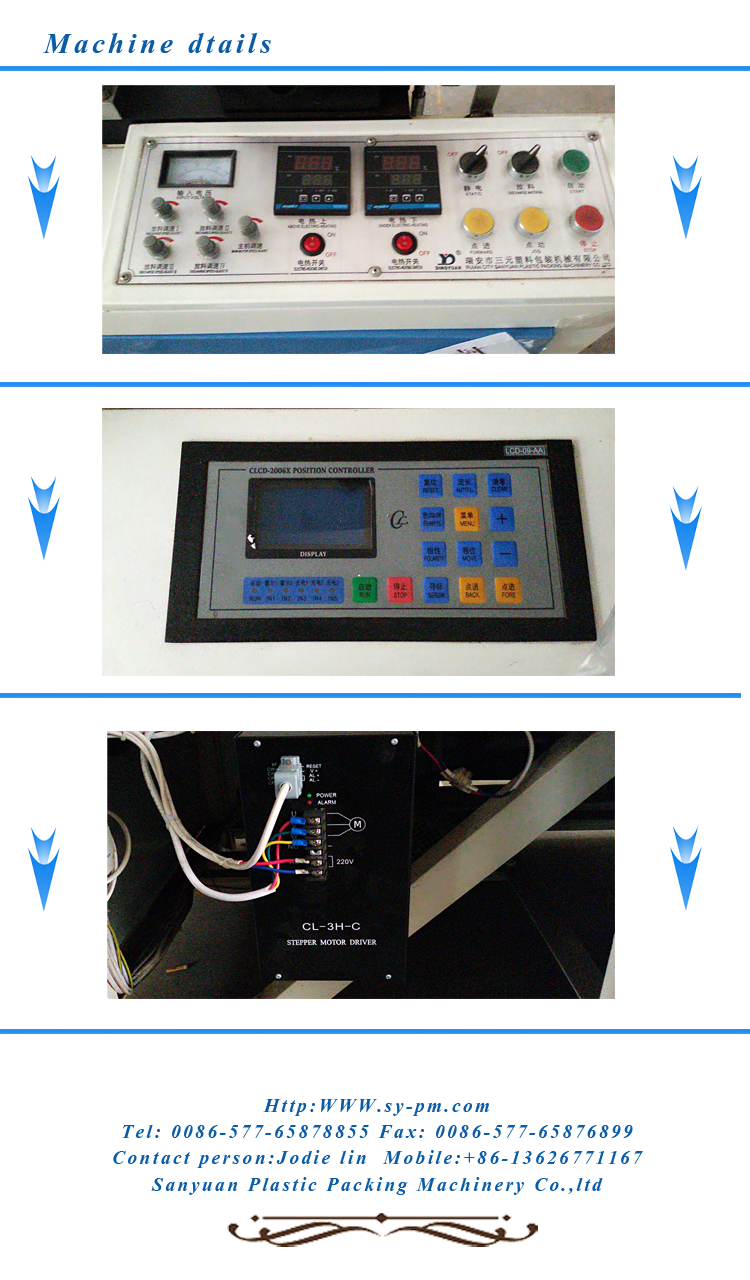

3.Computer control system:

The user can use the monitor control panel on the computer to read technical parameters, set bag length, working speed. It is very convenient.

4.Photo cell:

Photo cell is used for print bag to do one line production.

5.Photoelectric control feeding system:

This system is used to control film feeding system.

6.Automatic temperature control:

It adopts intelligent temperature controller to control the temperature easily.

7.Electric static mover bar:

It can treat the static on the film, the finished bags will easily go out and be smooth.

8.Automatic counting system:

User can set the numbers of bags by each bundle. The computer will automatically count it. In this way, the user can easily know the production of bags.

9.Alarm system:

When the machine finish the quantities of bags, which is set by the user. The alarm system will give alarm sound to reminder the user its near finishing job. Moreover, if the photo cell can not find the printed mark position, it will also alarm.

10.Running belt:

It is easy to send finished goods out with the green belt.

|

1 |

Model |

FQCT600 |

FQCT-700 |

FQCT-800 |

FQCT-1000 | |

|

2 |

FOB Ningbo port |

7000USD |

7800USD |

8500USD |

9700USD | |

|

3 |

Machine Name |

Bag.making.machine | ||||

|

4 |

Capacity |

120CUT/MIN*4 LINES |

120CUT/MIN*4 LINES |

120CUT/MIN*LINES |

120CUT/MIN*4 LINES | |

|

5 |

Bag Width (Max) |

500MM |

600MM |

700MM |

900MM | |

|

6 |

Bag Length |

100-1200MM |

100-1200MM |

100-1200MM |

100-1200MM | |

|

7 |

Converting Thickness |

0.01-0.10mm |

0.01-0.10mm |

0.01-0.10mm |

0.01-0.10mm | |

|

8 |

Accuracy Length |

±1 |

±1 |

±1 |

±1 | |

|

9 |

Motor |

1.1kw/1.5HP |

1.1kw/1.5HP |

1.1kw/1.5HP |

1.1kw/1.5HP | |

|

10 |

Heater |

2w |

2.3w |

2.5w |

3.5w | |

|

11 |

Power Required |

4KW |

4.2KW |

4.5KW |

5.5KW | |

|

12 |

Dimension (L×W×H) |

2900×1180×1900MM |

2900×1280×1900MM |

2900×1380×1900MM |

2900×1580×1900MM | |

|

13 |

Gross Weight |

600kg |

700kg |

800kg |

1000kg | |

|

14 |

Colors |

White and RED |

White and RED |

White and RED |

White and RED | |

|

15 |

HS Code |

84778000 |

84778000 |

84778000 |

84778000 | |

|

16 |

MOQ/Min order quantity |

1SET |

1SET |

1SET |

1SET | |

|

17 |

Lead Time |

On Receiving the deposit, the machine producing time is 30-35days | ||||

|

18 |

MACHINE VIDEO |

http://www.youtube.com/watch?v=g53q010ELhk | ||||

|

19 |

company introduction |

http://www.youtube.com/watch?v=k95kEm8LEhs | ||||

|

20 |

Remarks |

Please advise your film max width and thickness , we will design the machine according to your requirement. | ||||

FREE SPARE PARTS:

|

No. |

Spare parts name |

Quantity |

|

1 |

Front sending spring |

50pcs |

|

2 |

High temperature cloth |

1 PC |

|

3 |

wrench for Allen screws |

1set |

|

4 |

17-19 Offset ring spanner |

1pc |

|

5 |

8-10 spanner |

1pc |

|

6 |

Electric pen |

1 pc |

|

7 |

Oil stone |

1pc |

|

8 |

Oil gun |

1 pc |

|

9 |

Synchronic belt |

1pc |

|

10 |

Chick |

4pcs |

|

11 |

Book end |

8pcs |

|

12 |

English manual |

1 pc |

|

13 |

High temperature tape |

1box |

|

14 |

Temperature sensor |

2pcs |

|

15 |

Temperature controller |

1pc |

WORKSHOP

ANY NEED FOR PACKING MACHINE ,PLEASE FEEL FREE TO CONTACT US .