A- what material does this machine recycle

?

SJ100 model Single-stage Waste

Plastic Air cool Recycling Machine is used to recycle HDPE, and LDPE material.

B-

what advantages is this machine?

1- bubble free

2-moisture free,

no need water cool.

3-rapid screen

changer device ,

4-automatic

temperature controller.

C.

what is the machine more technical details?

1-

It produce

granules by following steps : 1- extruding , 2- hot cutting system 3- air

cooling.

2. It is equipped with automatic constant temperature,

motorized net changer (hydraulic net changer is optional).

3. It also can pelletize the crushing material after fitting

with an force loader.

4. The cutting machine adopts speed regulating

motor. Which can cut the material according to the feeding speed of the

extruder, with such features as high output, low noise, stable performance and

easy operation. It is a more ideal waste plastic film regenerative pelletizer.

5. Feeding unit adopts force feeder.

6. The helical gear reducer with hard teeth is applied to the

extruder and the screw.

7. Cylinder and screw are made of 38CrMoA1A with nitrogen

treatment.

D- Main

specification:

Output: 50-70kg/h

Applicable raw

material: HDPE/LDPE materials

Power supply: 380v, 50Hz 3 Phase (we can make machine electric system according to customer requirement)

Material of screw and barrel: Alloyed high-quality steel

38CrMoAlA

with optimum hardness and strong corrosion resistance after

precision finishing and nitrogen treatment

Gear box: Hard Surface Gear

Automatic temperature controlling system

Including water-cooling device made of stainless steel

Main Extrusion Unit

Main extruder

Main motor :22kw

Screw Diameter: Φ 97mm

barrel diameter 140mm

Screw length: 2200mm

E. Main Technical Parameters:

|

Machine Model |

SJ-100 |

|

|

Output |

HDPE |

50-70 kg/h |

|

Main Extruder Screw Size |

97mm |

|

|

hydraulic Screen Changer |

Yes |

|

|

Main Motor Size |

22kw |

|

|

Heating Power |

15kw |

|

|

Main Extruder screw length |

2200mm |

|

|

Main Motor Inverter |

22kw |

|

|

die head heat

cutting motor |

1.5kw |

|

|

die head heat

cutting motor inverter |

1.5kw |

|

|

heating ring |

ceramic |

|

|

cooling air

blower |

5.5kw |

|

|

second time

air blower |

2.2kw (big

force design ) |

|

|

Main Extruder Gear Box Hard Teeth |

400 Model |

|

|

automatic

temperature control |

5 zone |

|

|

material

sending pipe |

6m |

|

|

finished

material storage box |

1piece |

|

|

Machine Production Dimension |

5000*2500*1600mm | |

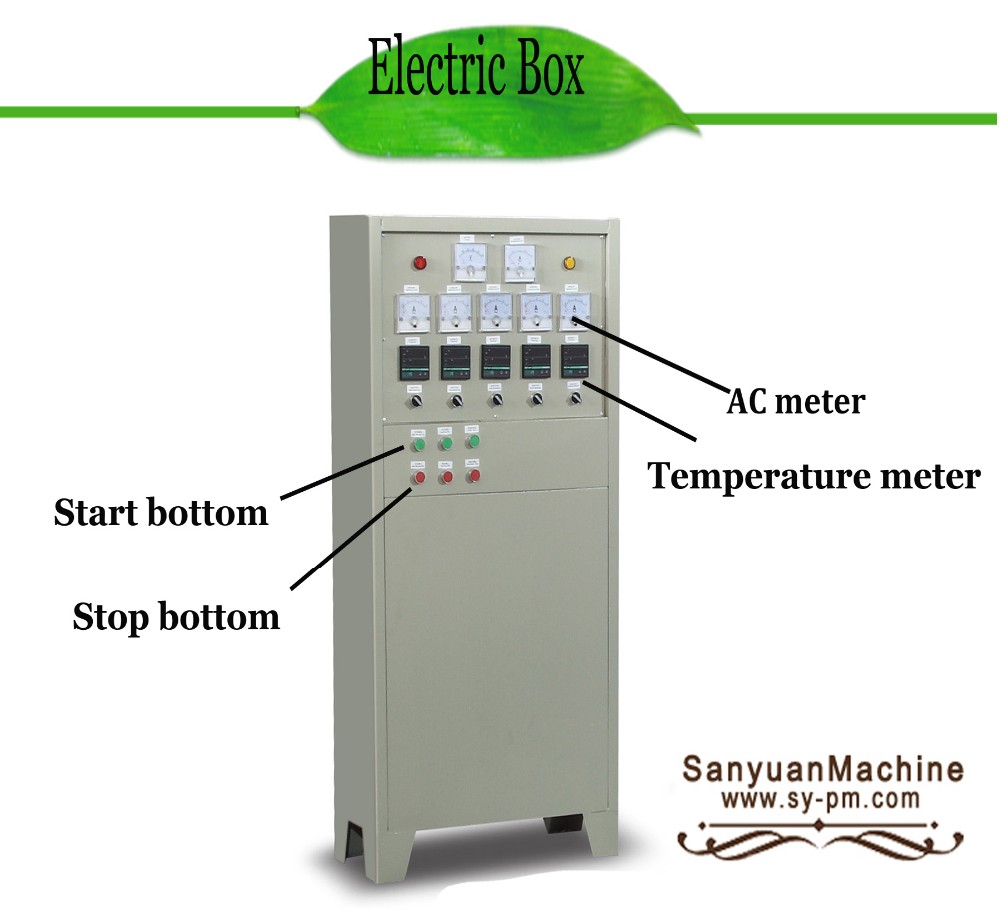

Main Spare part list:

|

SPARE PART NAME |

BRAND NAME |

ORIGIN |

CERTIFICATE |

|

1.Motor |

weinuo |

China |

CE

certificate |

|

2.Temperature

meter |

YT |

China |

CE

certificate |

|

3.Inverter |

pioneer |

China |

CE

certificate |

|

4.Button |

Chint |

China |

CE

certificate |

|

5.Breaker |

Chint |

China |

CE

certificate |

|

6.Contactor |

Chint |

China |

CE

certificate |

|

7.Ac meter |

Chint |

China |

CE

certificate |

|

8.Voltage

meter |

Chint |

China |

CE certificate |

|

No. |

Spare parts name |

Quantity |

|

1 |

Temperature meter |

1set |

|

2 |

Electric Sensor |

2 pc |

|

3 |

Heating ring |

3 pc |

|

4 |

ac meter |

1pc |

|

5 |

voltage meter |

1pc |

|

6 |

contact |

1pc |

|

7 |

temperature sensor |

2pc |

|

8 |

yellow color button |

2pc |

|

9 |

red color button |

2pc |

|

10 |

blue color button |

2pc |

|

11 |

breaker |

1pc |

|

12 |

Tool box |

1set |

|

13 |

English manual |

1pc |

FAQ:

1.

Q:

Are you a factory or trading company?

A: We are a factory

2.

Q:

Where is your factory located? How can I visit there?

A: Our factory is located in Ruian City, Zhejiang Province, China.The nearest airport is Wenzhou airport.about 40 minutes by plane from Shanghai(5 hours by train).All our clients, from home or abroad, are warmly welcomed to visited us!

3. Q: Can I get some samples? How can I get it?

A: Yes, we can send you some free samples, but you are responsable for delivery charges of TNT or DHL.

4. Q: How does your factory do the quality control?

A: "QUALITY IS

FIRST", We give importance to the quality controlling from the very

beginning to the end.Our factory has gained CE&SGS certificate